For aircraft, the 3D attitude of an object's spatial motion is the motion parameter used to deconstruct its flight state. 3D motion trajectory and 6-DOF (6-DOF) measurements of aircraft structural components are extremely valuable for aircraft design, testing, improvement, and fault analysis.

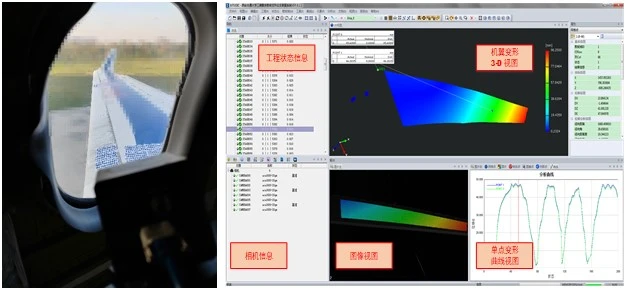

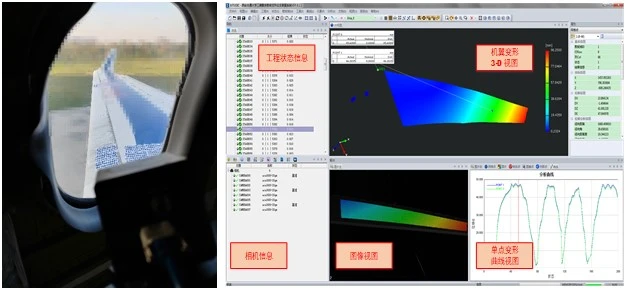

In actual flight, the trajectory, attitude, and undulating deformation of aircraft structural components are complex and highly variable, directly impacting the aircraft's in-flight safety and aerodynamic performance. Using Xintuo 3D's XTDIC-STROBE 3D dynamic measurement technology to determine the deformation distribution of an aircraft during flight helps improve flight reliability and shorten R&D and testing cycles.

DIC dynamic trajectory measurement in flight

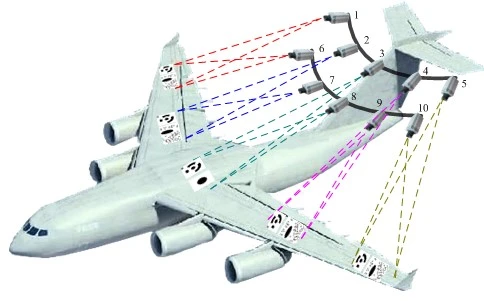

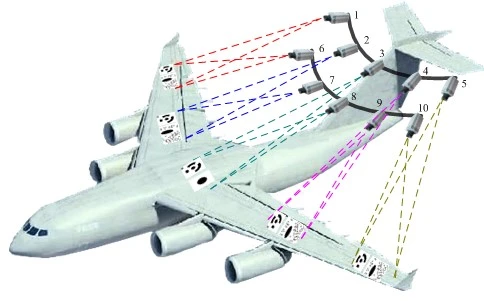

In modern aircraft performance testing, motion analysis of aircraft and their structural components is often based on theoretical simulations or wind tunnel experiments. The XTDIC-STROBE 3D dynamic measurement system from Xintuo 3D can measure the trajectory, attitude, displacement, and deformation of aircraft structural components and onboard objects during flight. A high-speed camera is mounted on the aircraft to capture real-time images during flight. DIC software is used for data analysis and processing, and outputs the measurement results.

The XTDIC-STROBE 3D dynamic measurement system, combined with high-speed camera image acquisition and DIC software, calculates the displacement and deformation of each landmark under load. It can be used to measure deformation and attitude of models in low-speed, high-speed, and ultra-high-speed wind tunnels; conduct structural dynamics testing on flexible wing models in supersonic wind tunnels to determine the displacement distribution during wing vibration; and measure wing deformation under actual aircraft flight conditions.

Elimination of airborne camera shake interference

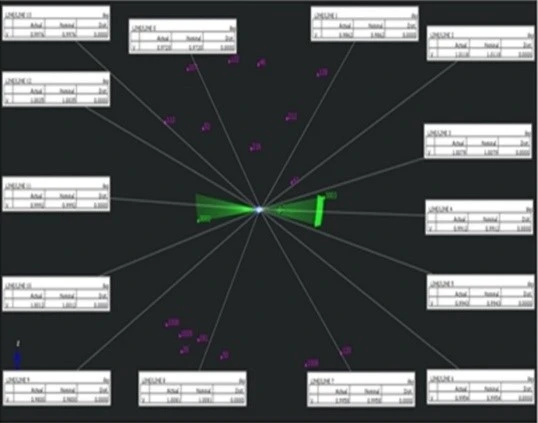

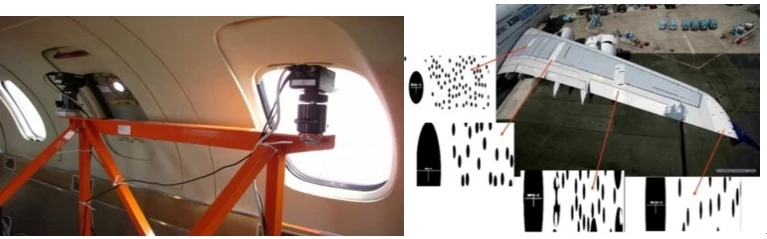

A dynamic camera positioning method is used. During flight, aircraft structural components vibrate irregularly, which in turn affects the onboard camera, interfering with the accuracy of digital image correlation (DIC) measurements.

Using known global control points, the XTDIC-STROBE 3D dynamic measurement system employs a spatial resection method to position the camera in real time, effectively eliminating measurement errors caused by camera shake.

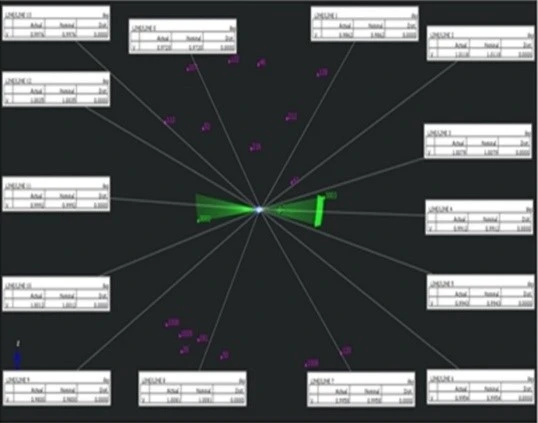

The single-image spatial resection solution uses the image coordinates of the control points as observations and solves for the image's interior and exterior orientation elements. Because the exterior orientation elements only have six unknowns, at least three control points are required. The single-image spatial resection algorithm is an iterative operation, employing a triangular pyramid algorithm from photogrammetry to calculate initial values.

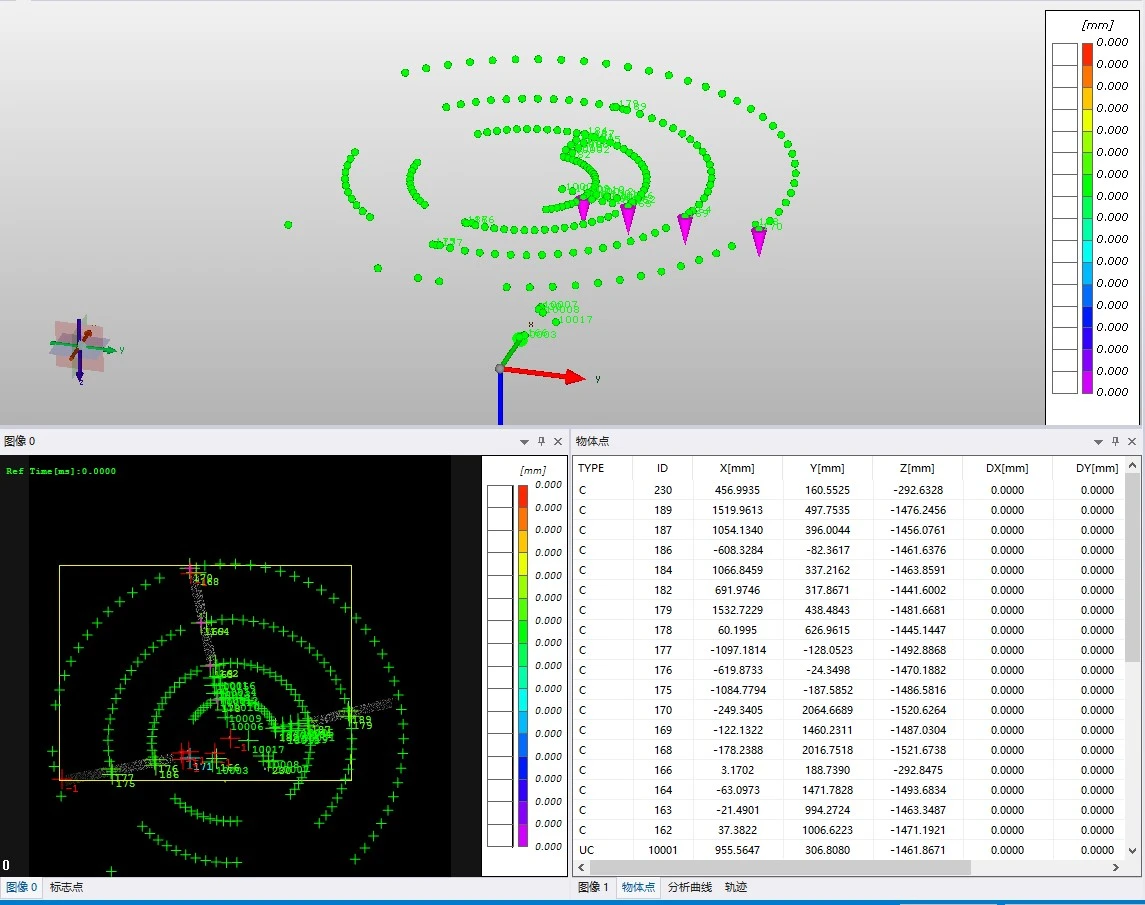

DIC camera dynamic positioning

During flight, the aircraft's structural components vibrate irregularly, but the overall flexible deformation of the fuselage's local rigid components is negligible relative to the rigid movement of the onboard camera. Therefore, the fuselage's rigid structural components are assumed to have no flexible deformation.

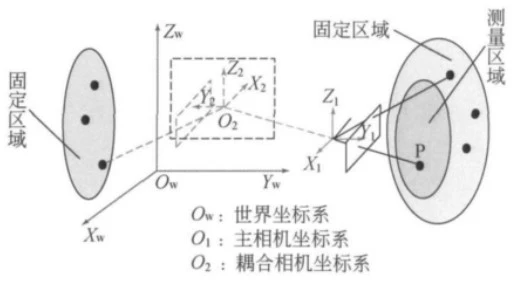

The camera positioning method is shown in the figure below. If the measurement camera can observe control points in a fixed area within its field of view, the spatial resection method is used to directly calculate the displacement pose and trajectory measurements.

Due to space limitations on the aircraft, when the main measurement camera cannot simultaneously observe the target area and the fixed area, a coupled camera method can be used to indirectly position the main measurement camera.

Camera dynamic positioning

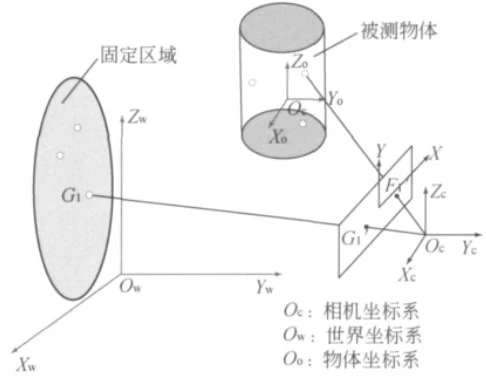

DIC trajectory attitude measurement

The flight test process requires precise measurement of the trajectory and attitude of an aircraft's rigid components. Traditional measurement methods for this problem rely on sensors, theodolites, or two-dimensional image tracking, which can only roughly estimate the aircraft's motion patterns and are qualitative analyses.

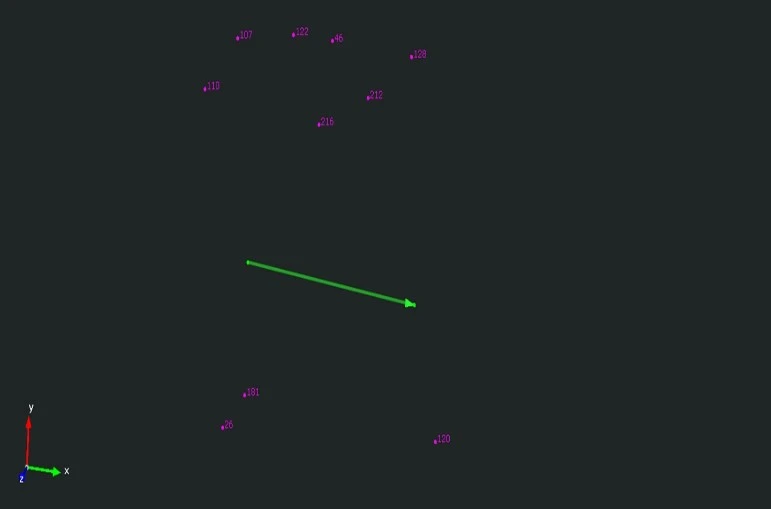

In flight data, attitude represents the target's rotation about three axes relative to a specific coordinate system. Based on the spatial resection method, the XTDIC-STROBE 3D dynamic measurement system can rapidly determine the trajectory and attitude of a rigid body's centroid. By analyzing the rigid body's landmarks, it accurately determines their 3D coordinates and inversely determines the rotation and translation matrices of the rigid body's coordinate system relative to the world coordinate system, thereby determining its attitude and trajectory.

Trajectory attitude measurement

Typical cases of trajectory attitude measurement

Aircraft attitude analysis in wind tunnel

The XTDIC-STROBE three-dimensional dynamic measurement system is used in conjunction with a high-speed camera to observe the aircraft's attitude, deformation, and local strain in the wind tunnel through the observation window.

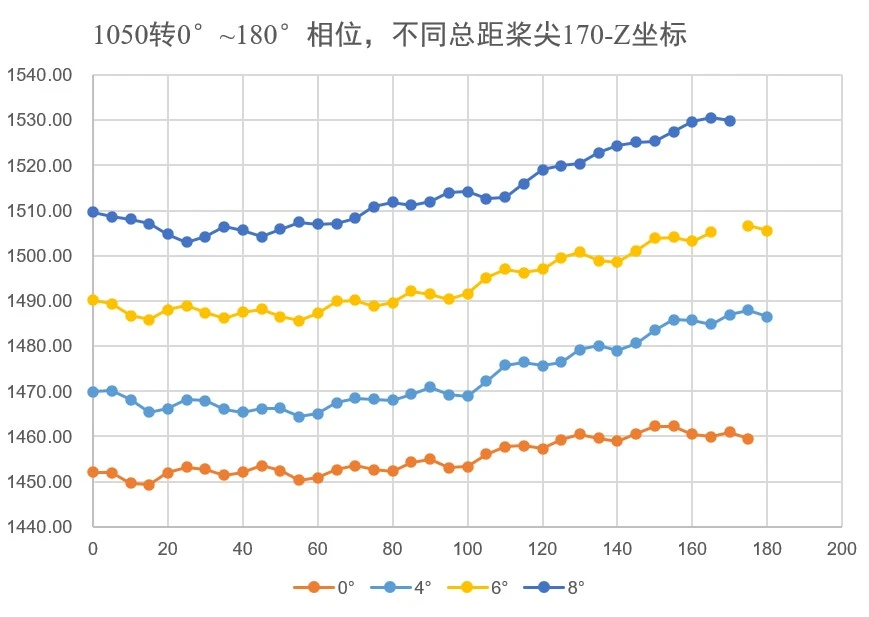

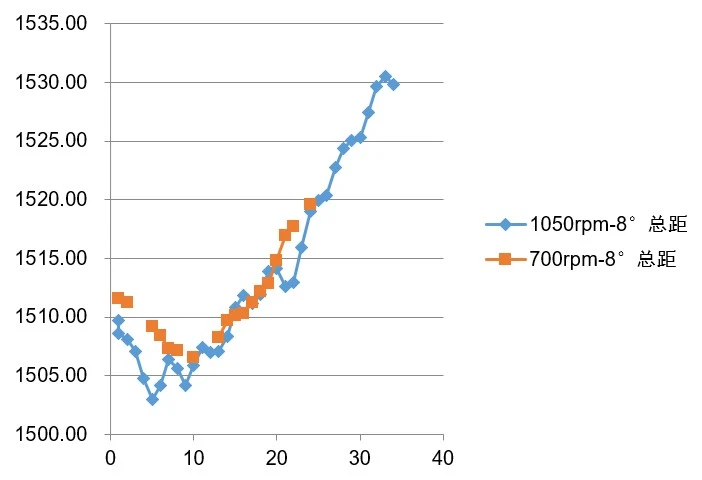

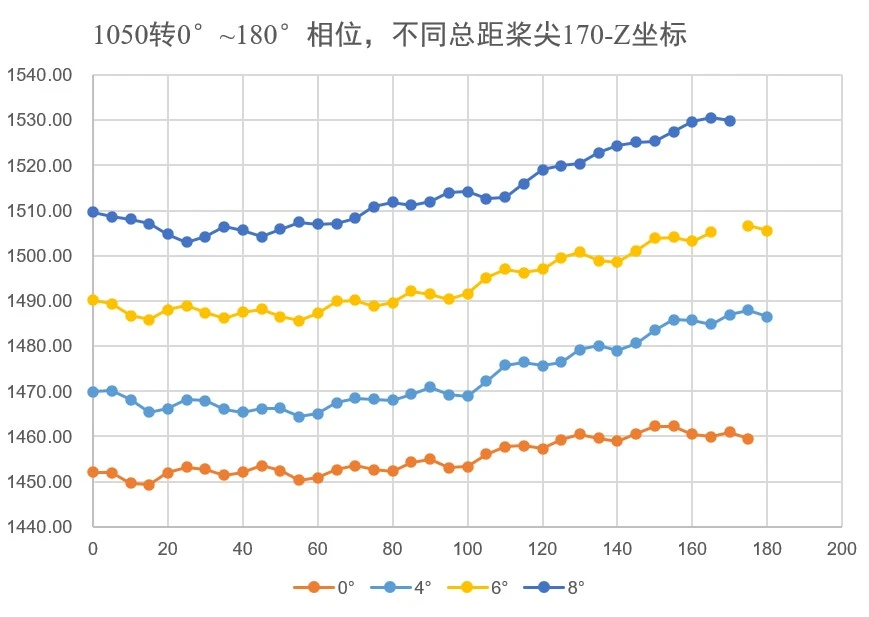

Analysis of helicopter rotor operating status

Missile Flight Trajectory Attitude Analysis

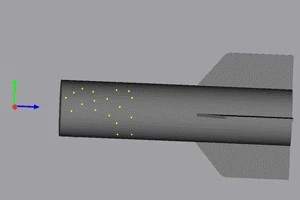

The XTDIC-STROBE 3D dynamic measurement system, coupled with a ground-based high-speed camera, captures images of the target within a defined observation window. This allows for analysis of the stress and deformation associated with missile launch, as well as missile attitude and trajectory tracking.

In-flight wing deformation test

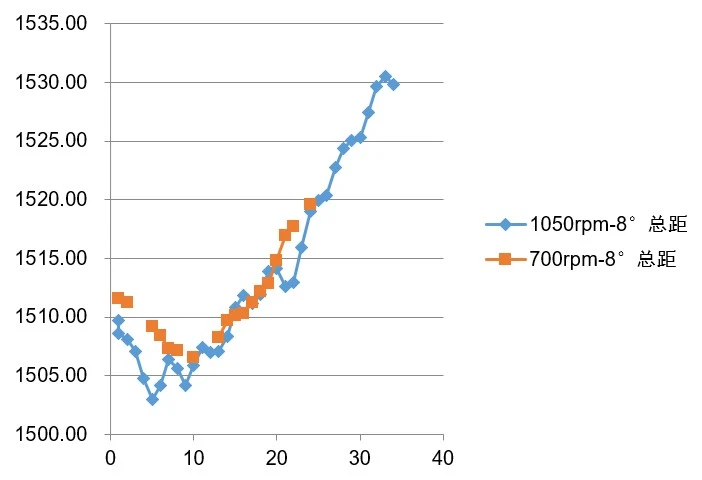

Multiple sets of XTDIC-STROBE three-dimensional dynamic measurement systems are used to undertake measurement and detection and conjugate vibration cancellation functions, realizing dynamic deformation monitoring of the wing.

Watch Video

Watch Video